It is a novel that guides you through the theory of constraints and production flow. It is also a good story. Rarely you would be interested in the life of a plant manager (Alex Rogo) and his marital issues but the authors captivate you with it.

Simplifications were not disregarded as tools for the story and were explained and challenged.

Dealing with software you hear about Kanban and Toyota and you think you know all about Lean principles but it is much more nuanced than having used Trello. Actually cards were never mentioned in the story.

The book dictates that to have continuous improvement you must operate on the following steps:

Simplifications were not disregarded as tools for the story and were explained and challenged.

Dealing with software you hear about Kanban and Toyota and you think you know all about Lean principles but it is much more nuanced than having used Trello. Actually cards were never mentioned in the story.

The book dictates that to have continuous improvement you must operate on the following steps:

- Identify the system’s bottlenecks.

- Decide how to exploit the bottlenecks.

- Subordinate everything else to the above decision.

- Elevate the system’s bottlenecks.

- If, in a previous step, a bottleneck has been broken go back to step 1.

As a result Rogo's plant was saved and even made a lot more money due to capacity being freed up.

While this worked for Rogo's plant the steps might be a little different in each case.

I thought about how we process things in our services and installation department and it is quite different than the processes where the works and parts are not fixed.

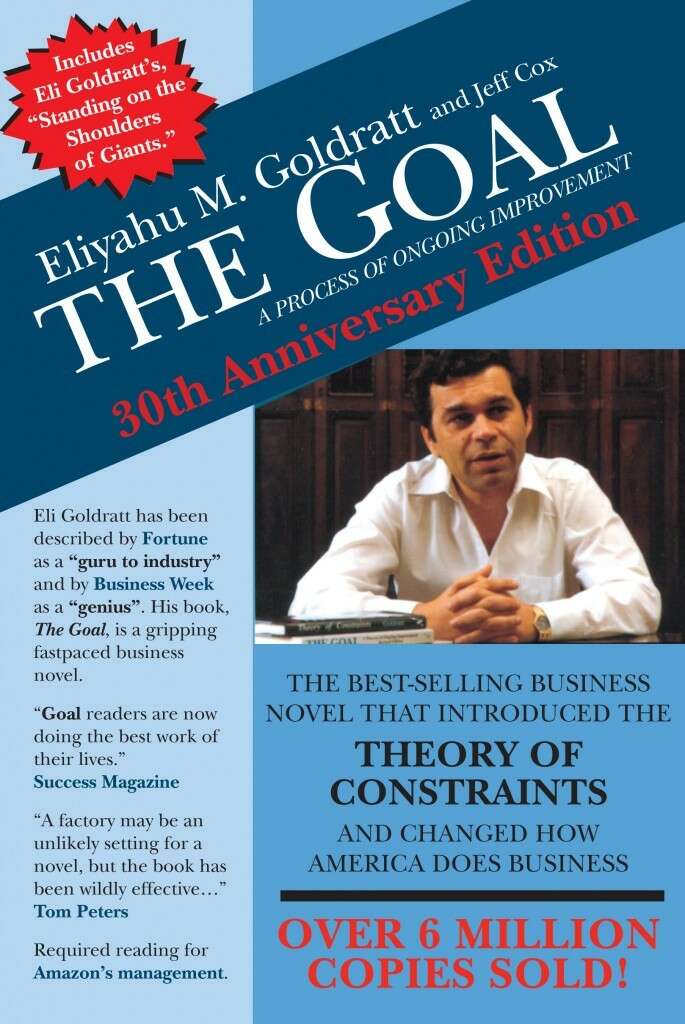

Many of these questions are covered inn the included paper Standing on the Shoulders of Giants – Production concepts versus production applications The Hitachi Tool Engineering example, Eliyahu M. Goldratt analyses how Henry Ford and Taiichi Ohno concepts for the flow of the production affected the industry and why some companies following their teachings failed.

He notes in my understanding that a plant like Hitachi Tool Engineering who followed all the good practices described by the two gentlemen was affected by the constant addition and deprecation of products which were not using the same components. The gains from all the improvements were killed as the production changed, making the improvement of the operation a Sisyphean task.

However to improve any process you can take away minding your bottlenecks while refraining from dealing with tasks that don't make money.